- Konu Yazar

- #1

Leuze’s FBPS 600i safe barcode reader now includes PROFIsafe interface, enabling direct connection to safety PLCs for positioning with Performance Level e in applications like crane positioning and assembly.

Leuze has recently announced the release of the FBPS 600i safety-rated barcode scanner with PROFIsafe interface that reports precise positions. This system is designed for use with safety PLCs in safe positioning applications like cranes, trolleys and assembly applications.

The FBPS 600i safe barcode positioning system can accurately report a position using a specially designed barcode tape, and because the reader can now communicate over PROFIsafe, the positioning system can be connected to a safety PLC.

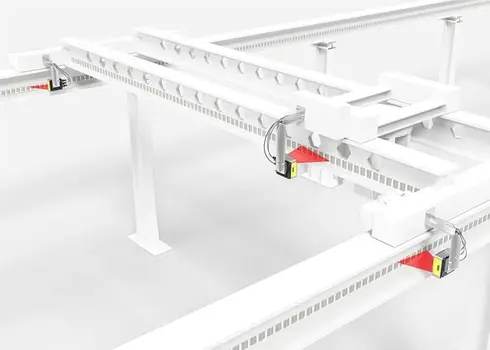

The FBPS 600i safety barcode reader now includes the PROFIsafe interface for connecting to a safety PLC

The FBPS 600i safety barcode reader now includes the PROFIsafe interface for connecting to a safety PLC. Image used courtesy of Leuze

The FBPS 600i safety barcode reader now includes the PROFIsafe interface for connecting to a safety PLC. Image used courtesy of Leuze

FBPS 600i Safe Positioning System

With the FBPS 600i barcode position system being safety rated to a PLe category, it can make use of safety functions like safe speed outputs, which are common when operators are nearby. For applications that don't require a safety reader, the FBPS 600i also has a non-safe SSI interface, which offers all the same precision as the safety-rated interface.

A sensor that reports the position of a crane needs to be reliable, so Leuze has developed its FBPS 600i to read the positioning barcode with an angled beam. The angled beam reads the codes at different points as the sensor is moved along the positioning tape. This design prevents errors and can accommodate slightly damaged tapes.

The FBPS 600i safe barcode positioning system features a 50 mm to 170 mm working range. Video used courtesy of Leuze The Sensor People

The FBPS 600i safe barcode positioning system features a 50 mm to 170 mm working range. Video used courtesy of Leuze The Sensor People

Mounting and Reading Distance

The FBPS

600i is ideal for use with stacker cranes, which are commonly used in the warehouse industry. These cranes need to fit in tight spaces with minimal clearance between the crane and the shelves. The FBPS 600i was designed with this in mind, so Leuze developed a one screw mounting feature. A clamp bracket is fixed to the crane or transfer car, and the FBPS 600i attaches to the clamp bracket with one screw. This bracket, combined with the 50 mm to 170 mm working range, allows the reader to be mounted in a variety of positions and easily removed for maintenance.

Configuration and Communication

Like most automation devices these days, the FBPS 600i series includes dual communications ports for linear topology, utilizing a standard M12 port. A mini USB port is provided for configuration through the integrated web server. Users can choose to configure the device through the PLC using a GSDML file.

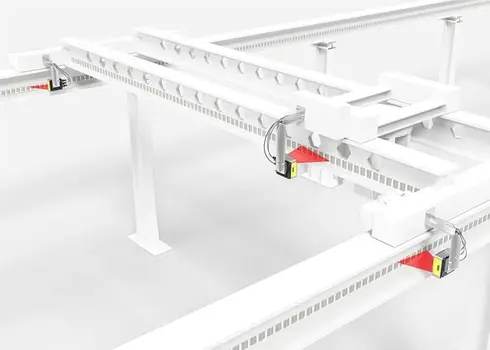

Leuze’s FBPS 600i safe bar code system relies on a one-screw fastening system that enables secure and accessible mounting

Leuze’s FBPS 600i safe barcode system relies on a one-screw fastening system that enables secure and accessible mounting. Image used courtesy of Leuze

Leuze’s FBPS 600i safe barcode system relies on a one-screw fastening system that enables secure and accessible mounting. Image used courtesy of Leuze

Detecting Long Range Motion

Cranes are devices that move heavy loads over long distances. When you want to know the position of the crane, it is not practical to use an encoder or distance sensor, so an optical device that reads the position on a tape is commonly used.

A specialized barcode reader is mounted on the moving part of the crane, while a high-quality tape with multiple barcodes printed on it is fixed to the opposite side of the reader. As the reader moves along the tape, the reader will capture multiple codes with each scan. Software is then used to determine the position.

Automated Warehouses

In an automated warehouse, products are stacked on shelves that reach to the very high ceilings, and the software that drives these cranes needs to know where they are. By using a device like the FBPS 600i, the warehouse process of stacking and destacking can safely be automated.

Leuze has recently announced the release of the FBPS 600i safety-rated barcode scanner with PROFIsafe interface that reports precise positions. This system is designed for use with safety PLCs in safe positioning applications like cranes, trolleys and assembly applications.

The FBPS 600i safe barcode positioning system can accurately report a position using a specially designed barcode tape, and because the reader can now communicate over PROFIsafe, the positioning system can be connected to a safety PLC.

The FBPS 600i safety barcode reader now includes the PROFIsafe interface for connecting to a safety PLC

The FBPS 600i safety barcode reader now includes the PROFIsafe interface for connecting to a safety PLC. Image used courtesy of Leuze

The FBPS 600i safety barcode reader now includes the PROFIsafe interface for connecting to a safety PLC. Image used courtesy of Leuze

FBPS 600i Safe Positioning System

With the FBPS 600i barcode position system being safety rated to a PLe category, it can make use of safety functions like safe speed outputs, which are common when operators are nearby. For applications that don't require a safety reader, the FBPS 600i also has a non-safe SSI interface, which offers all the same precision as the safety-rated interface.

A sensor that reports the position of a crane needs to be reliable, so Leuze has developed its FBPS 600i to read the positioning barcode with an angled beam. The angled beam reads the codes at different points as the sensor is moved along the positioning tape. This design prevents errors and can accommodate slightly damaged tapes.

The FBPS 600i safe barcode positioning system features a 50 mm to 170 mm working range. Video used courtesy of Leuze The Sensor People

The FBPS 600i safe barcode positioning system features a 50 mm to 170 mm working range. Video used courtesy of Leuze The Sensor People

Mounting and Reading Distance

The FBPS

600i is ideal for use with stacker cranes, which are commonly used in the warehouse industry. These cranes need to fit in tight spaces with minimal clearance between the crane and the shelves. The FBPS 600i was designed with this in mind, so Leuze developed a one screw mounting feature. A clamp bracket is fixed to the crane or transfer car, and the FBPS 600i attaches to the clamp bracket with one screw. This bracket, combined with the 50 mm to 170 mm working range, allows the reader to be mounted in a variety of positions and easily removed for maintenance.

Configuration and Communication

Like most automation devices these days, the FBPS 600i series includes dual communications ports for linear topology, utilizing a standard M12 port. A mini USB port is provided for configuration through the integrated web server. Users can choose to configure the device through the PLC using a GSDML file.

Leuze’s FBPS 600i safe bar code system relies on a one-screw fastening system that enables secure and accessible mounting

Leuze’s FBPS 600i safe barcode system relies on a one-screw fastening system that enables secure and accessible mounting. Image used courtesy of Leuze

Leuze’s FBPS 600i safe barcode system relies on a one-screw fastening system that enables secure and accessible mounting. Image used courtesy of Leuze

Detecting Long Range Motion

Cranes are devices that move heavy loads over long distances. When you want to know the position of the crane, it is not practical to use an encoder or distance sensor, so an optical device that reads the position on a tape is commonly used.

A specialized barcode reader is mounted on the moving part of the crane, while a high-quality tape with multiple barcodes printed on it is fixed to the opposite side of the reader. As the reader moves along the tape, the reader will capture multiple codes with each scan. Software is then used to determine the position.

Automated Warehouses

In an automated warehouse, products are stacked on shelves that reach to the very high ceilings, and the software that drives these cranes needs to know where they are. By using a device like the FBPS 600i, the warehouse process of stacking and destacking can safely be automated.