- Konu Yazar

- #1

A team of undergraduate students at the Swiss Federal Institute of Technology in Zurich has pioneered a 3D printing technology that generates multi-metal parts for the aerospace industry.

Students from the Swiss Federal Institute of Technology (ETH) Zurich have devised a unique prototype of a rotating, multi-metal making laser powder bed fusion (LPBF) 3D printing machine for making space aircraft components faster than conventional methods.

ETH Zurich students have developed a multi-metal 3D printing prototype that can print parts for the aerospace industry

ETH Zurich students have developed a multi-metal 3D printing prototype that can print parts for the aerospace industry. Image used courtesy of ETH Zurich

ETH Zurich students have developed a multi-metal 3D printing prototype that can print parts for the aerospace industry. Image used courtesy of ETH Zurich

Students Advancing Aerospace

The motivation for engineering this pioneering technology came from the need to create multi-metal bi-liquid rocket nozzles that can withstand demanding heat and pressure. The nozzles are hoped to be used as part of the Swiss Academic Space Initiative, ARIS. The ARIS association has a vision of reaching a boundary approximately 62 miles into space, marking the end of Earth’s atmosphere, known as the Kármán Line.

The Kármán Line, named after Hungarian physicist Theodore von Kármán, is the boundary at which Earth’s atmosphere ends and the atmosphere becomes too thin for aircraft to support themselves through the lift generated by their wings. To travel in the thin atmosphere and maintain flight, aircraft must travel very fast. Above the Kármán Line, aircraft must reach orbital velocity to fly or fall back to Earth.

Laser Powder Bed Fusion (LPBF)

In support of ARIS and under the Focus Project RAPTURE, a group of undergraduate students led by Senior Scientist Michael Tucker and Professor Markus Bambech at ETH Zurich has developed and tested a novel multi-metal, rotating 3D printer in just nine months.

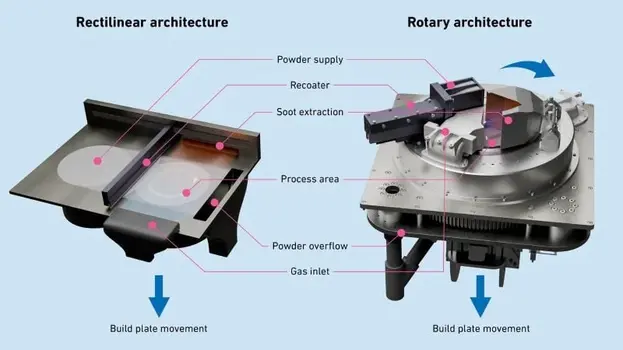

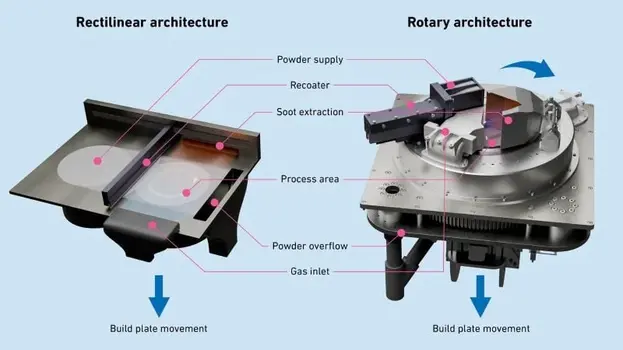

Comparing a conventional 3D printer with ETH Zurich’s RAPTURE device

Comparing a conventional 3D printer with ETH Zurich’s RAPTURE device. Image used courtesy of ETH Zurich

Comparing a conventional 3D printer with ETH Zurich’s RAPTURE device. Image used courtesy of ETH Zurich

Conventionally, LPBF 3D printing relies on the use of a powerful laser and the selection of an area of powder bed (composed of metal or polymer powder) from which to construct the desired part/component. The laser sinters/melts the powder, and when it fuses, the build platform is lowered to make space for the next layer to form. Powder is supplied through a reservoir or hopper, and a recoater blade spreads a thin layer of powder uniformly across the build platform, ready for laser-guided sintering. Once the part is made, it undergoes post-processing to meet safety and quality requirements.

A Multi-Metal, Rotating 3D Printer

Students’ newly devised RAPTURE machine differs from conventional LPBF printers in that it employs a unique rotating platform that allows the otherwise sequentially added powder-coated layers to be added and fused by the laser simultaneously. According to ETH Zurich, this is a significant advancement that cuts down the production of cylindrical parts by two-thirds.

The rotating platform of the RAPTURE device allows laser sintering to run continually and not just layer-by-layer as in conventional methods. Video used courtesy of ETH Zurich

The rotating platform of the RAPTURE device allows laser sintering to run continually and not just layer-by-layer as in conventional methods. Video used courtesy of ETH Zurich

Conventional systems typically use larger quantities of metal powder, and mixed powder setups are notoriously difficult to separate without incurring waste. The new RAPTURE 3D printer only deposits the necessary amount of powder for a given part, therefore avoiding unnecessary waste. The novel system also blows inert gas over the powder during laser fusi

on to prevent part oxidation. By-products of the process are extracted through an outlet.

Future Research and Applications

In just nine months, the students behind the creation of the RAPTURE machine created their own parts, including a rotating connection for the gas inlet and an automatic powder refill system. Aside from generating bespoke parts, the students also navigated the challenge of synchronizing the power supply, laser scanning, and rotating gas inlet.

At present, the research team feels that the newly developed prototype is well-suited for aerospace component generation, such as rocket nozzles, rotating engines, non-axisymmetric parts, and part arrays. Other application areas include those with ring-shaped geometries, such as electric motors, aircraft, and gas turbines.

The team seeks to collaborate with industry professionals to develop the RAPTURE device further, building upon the current prototype by enabling the printer to print components beyond a 20 cm diameter and maximizing printing speed for high-throughput operations.

Students from the Swiss Federal Institute of Technology (ETH) Zurich have devised a unique prototype of a rotating, multi-metal making laser powder bed fusion (LPBF) 3D printing machine for making space aircraft components faster than conventional methods.

ETH Zurich students have developed a multi-metal 3D printing prototype that can print parts for the aerospace industry

ETH Zurich students have developed a multi-metal 3D printing prototype that can print parts for the aerospace industry. Image used courtesy of ETH Zurich

ETH Zurich students have developed a multi-metal 3D printing prototype that can print parts for the aerospace industry. Image used courtesy of ETH Zurich

Students Advancing Aerospace

The motivation for engineering this pioneering technology came from the need to create multi-metal bi-liquid rocket nozzles that can withstand demanding heat and pressure. The nozzles are hoped to be used as part of the Swiss Academic Space Initiative, ARIS. The ARIS association has a vision of reaching a boundary approximately 62 miles into space, marking the end of Earth’s atmosphere, known as the Kármán Line.

The Kármán Line, named after Hungarian physicist Theodore von Kármán, is the boundary at which Earth’s atmosphere ends and the atmosphere becomes too thin for aircraft to support themselves through the lift generated by their wings. To travel in the thin atmosphere and maintain flight, aircraft must travel very fast. Above the Kármán Line, aircraft must reach orbital velocity to fly or fall back to Earth.

Laser Powder Bed Fusion (LPBF)

In support of ARIS and under the Focus Project RAPTURE, a group of undergraduate students led by Senior Scientist Michael Tucker and Professor Markus Bambech at ETH Zurich has developed and tested a novel multi-metal, rotating 3D printer in just nine months.

Comparing a conventional 3D printer with ETH Zurich’s RAPTURE device

Comparing a conventional 3D printer with ETH Zurich’s RAPTURE device. Image used courtesy of ETH Zurich

Comparing a conventional 3D printer with ETH Zurich’s RAPTURE device. Image used courtesy of ETH Zurich

Conventionally, LPBF 3D printing relies on the use of a powerful laser and the selection of an area of powder bed (composed of metal or polymer powder) from which to construct the desired part/component. The laser sinters/melts the powder, and when it fuses, the build platform is lowered to make space for the next layer to form. Powder is supplied through a reservoir or hopper, and a recoater blade spreads a thin layer of powder uniformly across the build platform, ready for laser-guided sintering. Once the part is made, it undergoes post-processing to meet safety and quality requirements.

A Multi-Metal, Rotating 3D Printer

Students’ newly devised RAPTURE machine differs from conventional LPBF printers in that it employs a unique rotating platform that allows the otherwise sequentially added powder-coated layers to be added and fused by the laser simultaneously. According to ETH Zurich, this is a significant advancement that cuts down the production of cylindrical parts by two-thirds.

The rotating platform of the RAPTURE device allows laser sintering to run continually and not just layer-by-layer as in conventional methods. Video used courtesy of ETH Zurich

The rotating platform of the RAPTURE device allows laser sintering to run continually and not just layer-by-layer as in conventional methods. Video used courtesy of ETH Zurich

Conventional systems typically use larger quantities of metal powder, and mixed powder setups are notoriously difficult to separate without incurring waste. The new RAPTURE 3D printer only deposits the necessary amount of powder for a given part, therefore avoiding unnecessary waste. The novel system also blows inert gas over the powder during laser fusi

on to prevent part oxidation. By-products of the process are extracted through an outlet.

Future Research and Applications

In just nine months, the students behind the creation of the RAPTURE machine created their own parts, including a rotating connection for the gas inlet and an automatic powder refill system. Aside from generating bespoke parts, the students also navigated the challenge of synchronizing the power supply, laser scanning, and rotating gas inlet.

At present, the research team feels that the newly developed prototype is well-suited for aerospace component generation, such as rocket nozzles, rotating engines, non-axisymmetric parts, and part arrays. Other application areas include those with ring-shaped geometries, such as electric motors, aircraft, and gas turbines.

The team seeks to collaborate with industry professionals to develop the RAPTURE device further, building upon the current prototype by enabling the printer to print components beyond a 20 cm diameter and maximizing printing speed for high-throughput operations.