- Konu Yazar

- #1

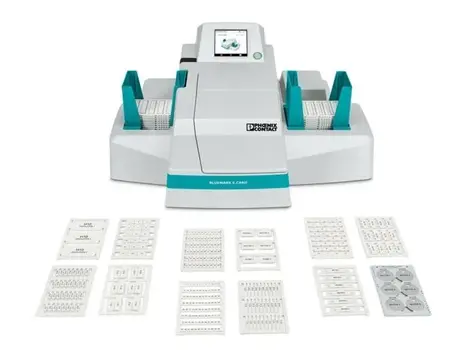

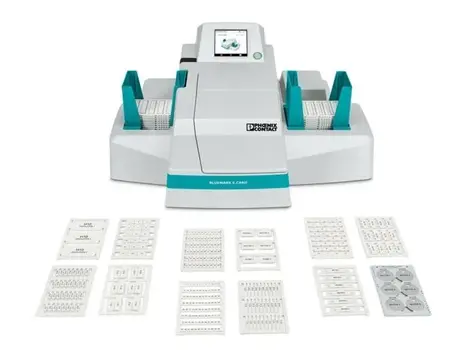

The new BLUEMARK E.CARD UV inkjet printer automates industrial card making for control cabinets and machine building, delivering durable, high-resolution marking with fast throughput.

Phoenix Contact’s new BLUEMARK E.CARD is a UV inkjet printer designed to speed up and simplify industrial labeling. The printer targets control cabinet builders and system manufacturers who face growing regulatory and operational demands for accurate component identification.

Phoenix Contact’s BLUEMARK E.CARD is a UV inkjet printer designed to simplify industrial card printing. Image used courtesy of Phoenix Contact

Phoenix Contact’s BLUEMARK E.CARD is a UV inkjet printer designed to simplify industrial card printing. Image used courtesy of Phoenix Contact

Phoenix Contact’s BLUEMARK E.CARD is a UV inkjet printer designed to simplify industrial card printing

Industrial Identification Standards

Labeling devices, components, and circuits is not only a best practice but a compliance requirement. Standards such as IEC 61436 set safety requirements for low-voltage switchgear, while EN IEC 81346 defines a uniform reference marking system for industrial systems throughout their lifecycle. Additionally, clear identification helps operators locate devices quickly, reduces downtime during servicing, and ensures consistent documentation across projects.

Phoenix Contact’s new UV inkjet printer, the BLUEMARK E.CARD, aims to address these needs by automatically printing durable, high-resolution labels capable of withstanding harsh industrial environments. The printer’s UV LED-curing inks produce markings that are reportedly scratch-resistant, chemical-resistant, and long-lasting.

BLUEMARK E.CARD UV Inkjet Printer

Unlike manual card-processing printers, the BLUEMARK E.CARD uses an automated card transport system. Operators can load up to 40 marker cards, which feed automatically into the device. Additional cards can be inserted without stopping the job, and each card requires less than 53 seconds to print.

Phoenix Contact highlights efficiency as a core benefit of its new printer, stating that the BLUEMARK E.CARD’s automated material processing saves users up to 40% of printing time compared to manual UV inkjet printers. This reduction in cycle time allows control cabinet and system manufacturers to accelerate project delivery while reducing operator workload.

The BLUEMARK E.CARD detects whether a card is plastic or metal and adjusts the ink formulation accordingly. Image used courtesy of Phoenix Contact

The BLUEMARK E.CARD detects whether a card is plastic or metal and adjusts the ink formulation accordingly. Image used courtesy of Phoenix Contact

Material Recognition and Modular Ink Concept

The BLUEMARK E.CARD integrates with Phoenix Contact’s MARKING system software to simplify setup and organize projects. The software detects misordered cards and prints them correctly, eliminating errors and wasted materials.

Each ink cartridge also includes a new printhead. This design reduces the need for maintenance and ensures consistently high-quality output. Cartridges can be stored in an onboard compartment when not in use, extending shelf life and minimizing unnecessary cleaning cycles.

Marking Software and Data Exchange

The BLUEMARK E.CARD detects whether a card is plastic or metal and adjusts the ink formulation accordingly

The BLUEMARK E.CARD integrates with Phoenix Contact’s MARKING system software, which aims to simplify setup and organize projects. The software detects misordered cards and prints them correctly, eliminating errors and wasted materials.

Through a bidirectional OPC UA communication interface, the printer supports network-supported data exchange, aligning with current Industry 4.0 practices. A built-in display provides real-time device and job information, giving operators full visibility during large-scale print runs.

Phoenix Contact’s MARKING system software enables users to monitor and execute print jobs via a bidirectional OPC UA communication interface. Image used courtesy of Phoenix Contact

Phoenix Contact’s MARKING system software enables users to monitor and execute print jobs via a bidirectional OPC UA communication interface. Image used courtesy of Phoenix Contact

Durable Marking in Demanding Environments

Control cabinet labels must endure varied conditions, from protected enclosures to areas exposed to mechanical and chemical stress. The BLUEMARK E.CARD’s UV curing process ensures markings remain legible and intact in these environments. The printer’s sharp typefaces and high contrast improve readability, while the ink’s resistance to wear reduces the need for re-labeling.

The combination of thermal inkjet technology and UV LED-curing inks provides application-specific performance for materials such as polycarbonate, polyamide, and metals. This versatility makes the device suitable across a broad range of industrial identification tasks.

Efficient Industrial Card Printing

For manufacturers, labeling is often a bottleneck. Manual systems require time-consuming card handling, while inconsistent markings risk non-compliance with industry standards. By automating transport, optimizing ink use, and integrating with networked workflows, the BLUEMARK E.CARD is positioned to make labeling a faster and more reliable step in cabinet and system production.

Featured image used courtesy of Phoenix Contact

Featured image used courtesy of Phoenix Contact

Phoenix Contact’s MARKING system software enables users to monitor and execute print jobs via a bidirectional OPC UA communication interface

Phoenix Contact’s new BLUEMARK E.CARD is a UV inkjet printer designed to speed up and simplify industrial labeling. The printer targets control cabinet builders and system manufacturers who face growing regulatory and operational demands for accurate component identification.

Phoenix Contact’s BLUEMARK E.CARD is a UV inkjet printer designed to simplify industrial card printing. Image used courtesy of Phoenix Contact

Phoenix Contact’s BLUEMARK E.CARD is a UV inkjet printer designed to simplify industrial card printing. Image used courtesy of Phoenix Contact

Phoenix Contact’s BLUEMARK E.CARD is a UV inkjet printer designed to simplify industrial card printing

Industrial Identification Standards

Labeling devices, components, and circuits is not only a best practice but a compliance requirement. Standards such as IEC 61436 set safety requirements for low-voltage switchgear, while EN IEC 81346 defines a uniform reference marking system for industrial systems throughout their lifecycle. Additionally, clear identification helps operators locate devices quickly, reduces downtime during servicing, and ensures consistent documentation across projects.

Phoenix Contact’s new UV inkjet printer, the BLUEMARK E.CARD, aims to address these needs by automatically printing durable, high-resolution labels capable of withstanding harsh industrial environments. The printer’s UV LED-curing inks produce markings that are reportedly scratch-resistant, chemical-resistant, and long-lasting.

BLUEMARK E.CARD UV Inkjet Printer

Unlike manual card-processing printers, the BLUEMARK E.CARD uses an automated card transport system. Operators can load up to 40 marker cards, which feed automatically into the device. Additional cards can be inserted without stopping the job, and each card requires less than 53 seconds to print.

Phoenix Contact highlights efficiency as a core benefit of its new printer, stating that the BLUEMARK E.CARD’s automated material processing saves users up to 40% of printing time compared to manual UV inkjet printers. This reduction in cycle time allows control cabinet and system manufacturers to accelerate project delivery while reducing operator workload.

The BLUEMARK E.CARD detects whether a card is plastic or metal and adjusts the ink formulation accordingly. Image used courtesy of Phoenix Contact

The BLUEMARK E.CARD detects whether a card is plastic or metal and adjusts the ink formulation accordingly. Image used courtesy of Phoenix Contact

Material Recognition and Modular Ink Concept

The BLUEMARK E.CARD integrates with Phoenix Contact’s MARKING system software to simplify setup and organize projects. The software detects misordered cards and prints them correctly, eliminating errors and wasted materials.

Each ink cartridge also includes a new printhead. This design reduces the need for maintenance and ensures consistently high-quality output. Cartridges can be stored in an onboard compartment when not in use, extending shelf life and minimizing unnecessary cleaning cycles.

Marking Software and Data Exchange

The BLUEMARK E.CARD detects whether a card is plastic or metal and adjusts the ink formulation accordingly

The BLUEMARK E.CARD integrates with Phoenix Contact’s MARKING system software, which aims to simplify setup and organize projects. The software detects misordered cards and prints them correctly, eliminating errors and wasted materials.

Through a bidirectional OPC UA communication interface, the printer supports network-supported data exchange, aligning with current Industry 4.0 practices. A built-in display provides real-time device and job information, giving operators full visibility during large-scale print runs.

Phoenix Contact’s MARKING system software enables users to monitor and execute print jobs via a bidirectional OPC UA communication interface. Image used courtesy of Phoenix Contact

Phoenix Contact’s MARKING system software enables users to monitor and execute print jobs via a bidirectional OPC UA communication interface. Image used courtesy of Phoenix Contact

Durable Marking in Demanding Environments

Control cabinet labels must endure varied conditions, from protected enclosures to areas exposed to mechanical and chemical stress. The BLUEMARK E.CARD’s UV curing process ensures markings remain legible and intact in these environments. The printer’s sharp typefaces and high contrast improve readability, while the ink’s resistance to wear reduces the need for re-labeling.

The combination of thermal inkjet technology and UV LED-curing inks provides application-specific performance for materials such as polycarbonate, polyamide, and metals. This versatility makes the device suitable across a broad range of industrial identification tasks.

Efficient Industrial Card Printing

For manufacturers, labeling is often a bottleneck. Manual systems require time-consuming card handling, while inconsistent markings risk non-compliance with industry standards. By automating transport, optimizing ink use, and integrating with networked workflows, the BLUEMARK E.CARD is positioned to make labeling a faster and more reliable step in cabinet and system production.

Featured image used courtesy of Phoenix Contact

Featured image used courtesy of Phoenix Contact

Phoenix Contact’s MARKING system software enables users to monitor and execute print jobs via a bidirectional OPC UA communication interface