- Konu Yazar

- #1

RoboBallet from Google DeepMind and Intrinsic uses AI to generate collision-free robot motion plans in seconds, replacing weeks of manual coding.

RoboBallet, developed by Google DeepMind Robotics, Intrinsic, and University College London, reimagines robot programming through AI. Instead of weeks of manual coding, the system generates collision-free multi-robot motion plans in seconds by combining graph neural networks with reinforcement learning. Robots move in harmony, like dancers on a stage, scaling efficiently from four to eight arms. With potential applications in automotive, electronics, and beyond, RoboBallet shifts engineers’ roles from coding paths to defining higher-level tasks and goals.

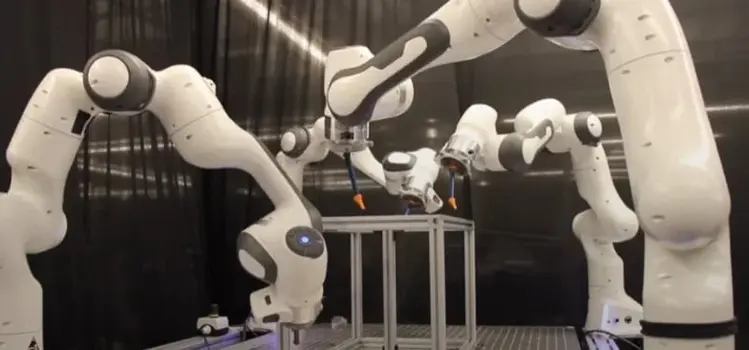

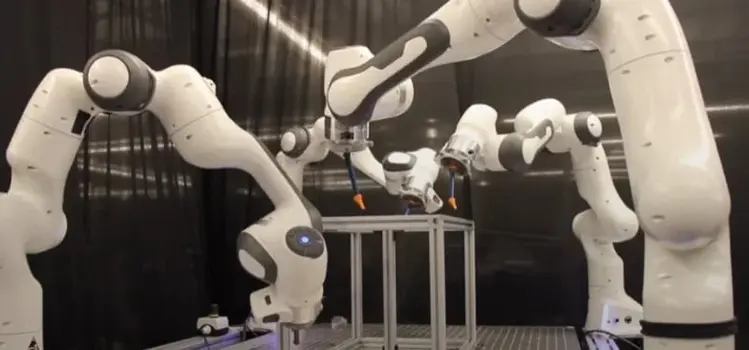

RoboBallet uses AI to coordinate multiple robots, generating collision-free motion plans in seconds instead of weeks of manual programming. Image used courtesy of Intrinsic.

RoboBallet uses AI to coordinate multiple robots, generating collision-free motion plans in seconds instead of weeks of manual programming. Image used courtesy of Intrinsic.ai

RoboBallet uses AI to coordinate multiple robots, generating collision-free motion plans in seconds instead of weeks of manual programming. Image used courtesy of Intrinsic.ai

A new project from Google DeepMind Robotics, Intrinsic, and University College London offers a fresh take. The system is called RoboBallet, and the name says a lot: instead of stiff machines grinding through prewritten scripts, robots look like dancers moving in harmony. Using AI, the platform can generate collision-free motion plans for multiple robots in just seconds, turning what used to be weeks of human programming into a smooth, automated routine.

Why Multi-Robot Planning Is So Hard

Programming even just two robots in the same workspace makes things difficult enough, but when you add a few more robots, the programming can get ugly fast. Not to mention, add obstacles, changing layouts, and eight robotic arms working side by side, and the number of possible paths explodes into the billions. Classical algorithms

bog down, leaving human specialists to babysit the process with rule tweaks and endless test runs. Worse, if the factory layout shifts or a new part is introduced, much of that effort gets tossed out, and the process starts again.

How RoboBallet Pulls It Off

The trick lies in combining two strands of AI. First, a graphical neural network maps the entire workspace as a web of nodes and connections, where robots, obstacles, and tasks are all part of the same graph. Then reinforcement learning teaches the system through trial and error, rewarding it for finding faster, safer solutions. After being trained on millions of simulated scenes, RoboBallet can step into a brand-new layout, read the CAD files, and develop efficient motion paths in seconds. No hand coding, no teach pendants, no annotated datasets.

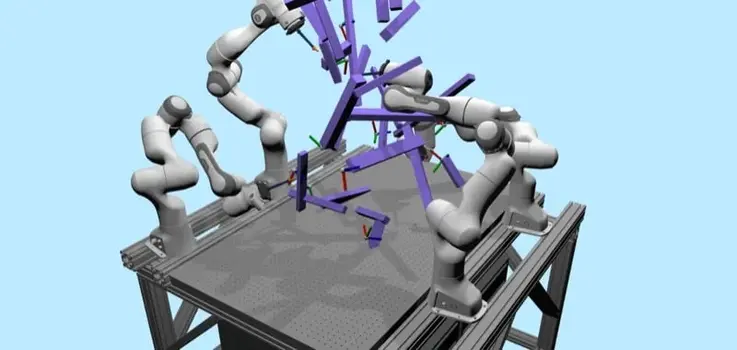

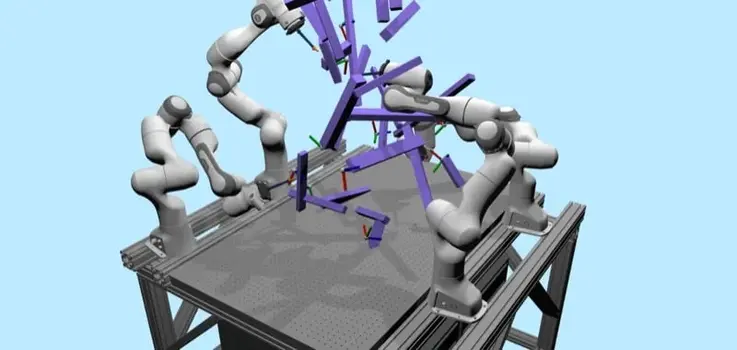

RoboBallet combines graph neural networks and reinforcement learning to quickly generate efficient, collision-free robot motion plans from CAD layouts. Image used courtesy of Instrinsic.

RoboBallet combines graph neural networks and reinforcement learning to quickly generate efficient, collision-free robot motion plans from CAD layouts. Image used courtesy of Instrinsic.ai

RoboBallet combines graph neural networks and reinforcement learning to quickly generate efficient, collision-free robot motion plans from CAD layouts. Image used courtesy of Instrinsic.ai

Putting More Robots on Stage

Adding robots usually makes coordination harder, yet here it does the opposite. In tests, RoboBallet scaled from four to eight arms, cutting average execution times by 60 percent. The motion paths weren’t just safe, they were tighter and more efficient, roughly 25 percent better than expert-written plans. What used to take weeks of careful design could now be handled in the time it takes to open a file. That speed makes sense in industries where robots already work shoulder to shoulder, like automotive

welding, electronics assembly, or even future construction sites packed with automated helpers.

The demonstration addresses one of the most persistent challenges in robotics: the collision-free coordination of multiple robots in a shared workspace. Video used courtesy of Intrinsic.ai

The demonstration addresses one of the most persistent challenges in robotics: the collision-free coordination of multiple robots in a shared workspace. Video used courtesy of Intrinsic.ai

Imagine a car plant where welding robots instantly replan if a part is slightly off, or an electronics line that keeps running smoothly even if one robot suddenly goes down. RoboBallet shifts the role of human engineers away from writing thousands of lines of code and toward defining the bigger picture: the goals, the boundaries, the tasks. The AI handles the messy middle, ensuring everything fits together without collisions or wasted motion.

Not Quite Perfect Yet

Currently, RoboBallet focuses on reaching tasks like welding or inspection, where arms move to set points. More complicated jobs like pick-and-place, painting, and complex task sequences are still on the horizon. Its flexible design, however, means those capabilities could be added in future iterations. Researchers see a future where operators define the “what” and the AI takes care of the “how,” adapting in real time if layouts change, parts shift, or even if a robot fails mid-task.

Programming robots by hand has slowed automation for years, wasting time and resources with every new task. RoboBallet points to a different way forward, where robots don’t have to be micromanaged line by line but can coordinate independently, almost like a troupe of dancers sharing the same stage. If the system keeps working outside the lab, factories could feel less rigid and more adaptable, able to shift gears without stopping the show.

RoboBallet, developed by Google DeepMind Robotics, Intrinsic, and University College London, reimagines robot programming through AI. Instead of weeks of manual coding, the system generates collision-free multi-robot motion plans in seconds by combining graph neural networks with reinforcement learning. Robots move in harmony, like dancers on a stage, scaling efficiently from four to eight arms. With potential applications in automotive, electronics, and beyond, RoboBallet shifts engineers’ roles from coding paths to defining higher-level tasks and goals.

RoboBallet uses AI to coordinate multiple robots, generating collision-free motion plans in seconds instead of weeks of manual programming. Image used courtesy of Intrinsic.

RoboBallet uses AI to coordinate multiple robots, generating collision-free motion plans in seconds instead of weeks of manual programming. Image used courtesy of Intrinsic.ai

RoboBallet uses AI to coordinate multiple robots, generating collision-free motion plans in seconds instead of weeks of manual programming. Image used courtesy of Intrinsic.ai

A new project from Google DeepMind Robotics, Intrinsic, and University College London offers a fresh take. The system is called RoboBallet, and the name says a lot: instead of stiff machines grinding through prewritten scripts, robots look like dancers moving in harmony. Using AI, the platform can generate collision-free motion plans for multiple robots in just seconds, turning what used to be weeks of human programming into a smooth, automated routine.

Why Multi-Robot Planning Is So Hard

Programming even just two robots in the same workspace makes things difficult enough, but when you add a few more robots, the programming can get ugly fast. Not to mention, add obstacles, changing layouts, and eight robotic arms working side by side, and the number of possible paths explodes into the billions. Classical algorithms

bog down, leaving human specialists to babysit the process with rule tweaks and endless test runs. Worse, if the factory layout shifts or a new part is introduced, much of that effort gets tossed out, and the process starts again.

How RoboBallet Pulls It Off

The trick lies in combining two strands of AI. First, a graphical neural network maps the entire workspace as a web of nodes and connections, where robots, obstacles, and tasks are all part of the same graph. Then reinforcement learning teaches the system through trial and error, rewarding it for finding faster, safer solutions. After being trained on millions of simulated scenes, RoboBallet can step into a brand-new layout, read the CAD files, and develop efficient motion paths in seconds. No hand coding, no teach pendants, no annotated datasets.

RoboBallet combines graph neural networks and reinforcement learning to quickly generate efficient, collision-free robot motion plans from CAD layouts. Image used courtesy of Instrinsic.

RoboBallet combines graph neural networks and reinforcement learning to quickly generate efficient, collision-free robot motion plans from CAD layouts. Image used courtesy of Instrinsic.ai

RoboBallet combines graph neural networks and reinforcement learning to quickly generate efficient, collision-free robot motion plans from CAD layouts. Image used courtesy of Instrinsic.ai

Putting More Robots on Stage

Adding robots usually makes coordination harder, yet here it does the opposite. In tests, RoboBallet scaled from four to eight arms, cutting average execution times by 60 percent. The motion paths weren’t just safe, they were tighter and more efficient, roughly 25 percent better than expert-written plans. What used to take weeks of careful design could now be handled in the time it takes to open a file. That speed makes sense in industries where robots already work shoulder to shoulder, like automotive

welding, electronics assembly, or even future construction sites packed with automated helpers.

The demonstration addresses one of the most persistent challenges in robotics: the collision-free coordination of multiple robots in a shared workspace. Video used courtesy of Intrinsic.ai

The demonstration addresses one of the most persistent challenges in robotics: the collision-free coordination of multiple robots in a shared workspace. Video used courtesy of Intrinsic.ai

Imagine a car plant where welding robots instantly replan if a part is slightly off, or an electronics line that keeps running smoothly even if one robot suddenly goes down. RoboBallet shifts the role of human engineers away from writing thousands of lines of code and toward defining the bigger picture: the goals, the boundaries, the tasks. The AI handles the messy middle, ensuring everything fits together without collisions or wasted motion.

Not Quite Perfect Yet

Currently, RoboBallet focuses on reaching tasks like welding or inspection, where arms move to set points. More complicated jobs like pick-and-place, painting, and complex task sequences are still on the horizon. Its flexible design, however, means those capabilities could be added in future iterations. Researchers see a future where operators define the “what” and the AI takes care of the “how,” adapting in real time if layouts change, parts shift, or even if a robot fails mid-task.

Programming robots by hand has slowed automation for years, wasting time and resources with every new task. RoboBallet points to a different way forward, where robots don’t have to be micromanaged line by line but can coordinate independently, almost like a troupe of dancers sharing the same stage. If the system keeps working outside the lab, factories could feel less rigid and more adaptable, able to shift gears without stopping the show.